In p75 such hours are substituted but in mats these hours are treated as missing data hours in the semi annual compliance report and require mats derived values to receive special modc codes this is usually done with a condition manager that looks at hourly data to see if so2ppm or the p75 stack flow parameter was fse and if so.

Mats compliance costs.

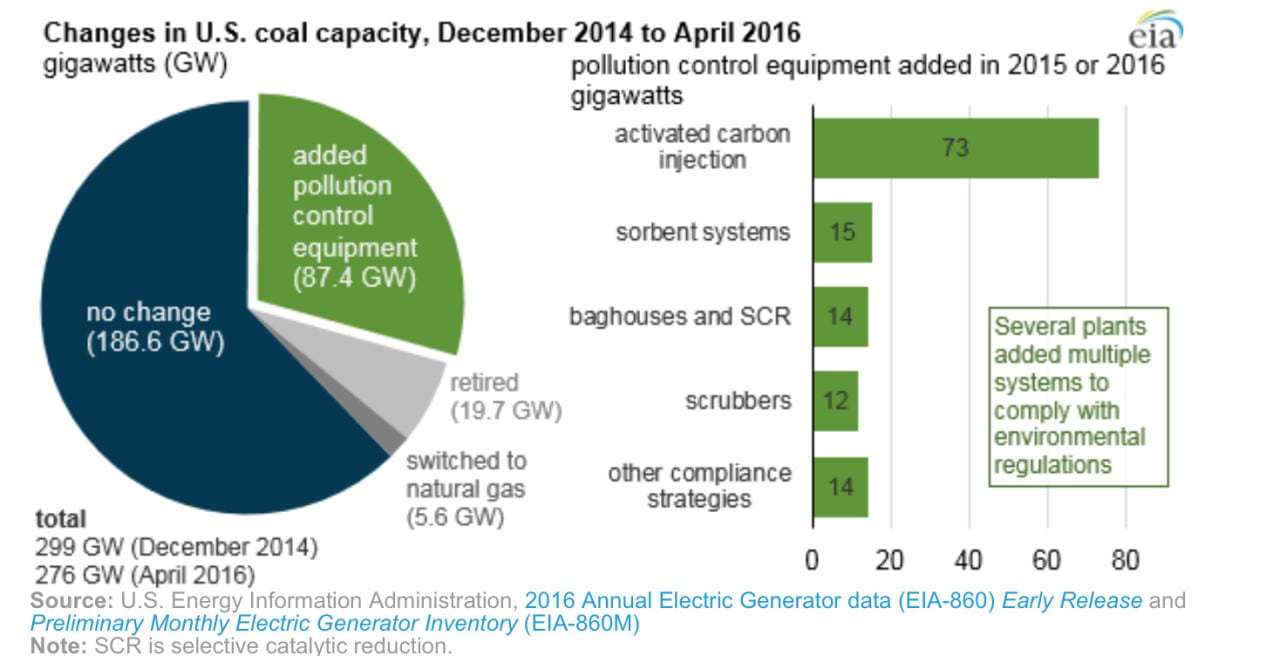

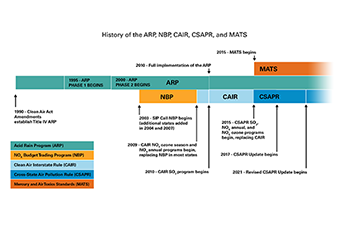

The mats requires that coal fired power plants incorporate the maximum achievable control technologies mact in order to control the emissions of acid gases toxic metals and mercury by april 2015.

After primarily considering compliance costs relative to the hap benefits of mats epa is concluding that it is not appropriate and necessary to regulate electric utility steam generating units under section 112 of the clean air act caa.

The total reduction in capital over 5 years at these facilities including 275 million for.

Issue 10 and volume 117.

The rule includes a provision that allows state environmental permitting agencies to grant one year compliance exemptions.

Our strategically optimized solutions sos for mats compliance put your existing pollution control systems to work to maximize mercury oxidation and removal and save you money.

Aecom process technologies can reduce operating costs increase mercury control system reliability and improve the flexibility of plant operations.

In section 5 of the executive summary the 2011 mats ria discussed several factors.

Annualized compliance costs over the time frame range from 7 4 to 9 6 billion 2007.

As a result of these closures our mats compliance costs are expected to decrease from around 925 million to approximately 650 million.

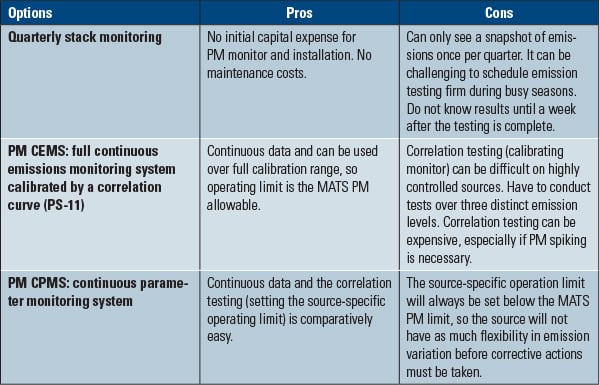

Developing a low cost mats rule compliance strategy.